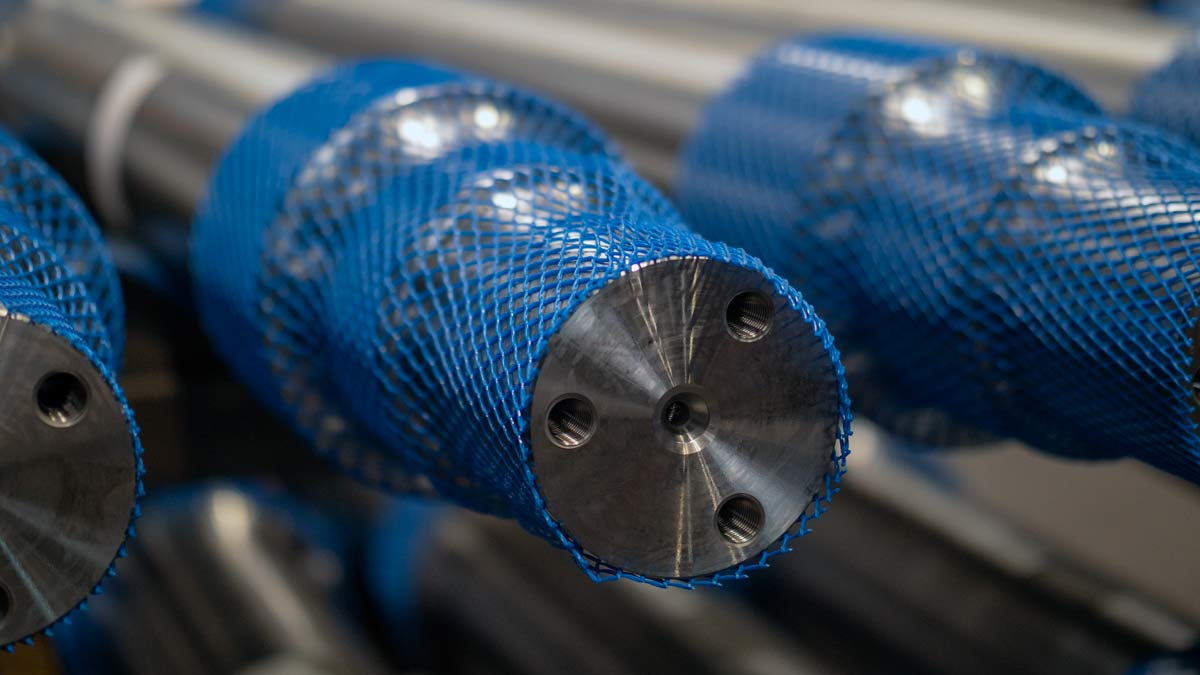

Our BVV axles with outstanding service life are not a coincidence – and here are five reasons for it: the careful selection of materials, the superior construction, the elaborate forging, the high-quality coating and of course the mechanical processing on state-of-the-art processing machines.

Axle

Tried and tested high-end quality

The material

Purpose and customer requests define the steel. Our quality meets the highest standards –thoroughly and extensively tested and proven a thousand times over.

The construction

The wheelset axles of each vehicle series are usually unique. Matched to the respective application and provided with the interfaces defined by the chassis, all axles are optimised under the guiding principles of robustness and longevity. Of course, services such as the determination of service test intervals, for example, are also part of the portfolio.

The surface treatment methods

All common heat and surface treatment methods are available to our customers: Cold rolling, shot blasting, molybdenum coating and more. As a premium treatment, we recommend a chemical-thermal process because it performs best in comparative tests: By nitrating the gas flow, it penetrates deep into the material, positively changes its properties and increases the resistance of the material sustainably.

Our axle offer

Driven and trailing wheelset axles

We offer both options with one and the same quality assurance.

Solid or hollow-bored

Weight or service aspects determine the choice – but no matter what you choose: Quality and longevity are guaranteed.

For all rail vehicles

We deliver axles for all types of rail vehicles

- High-speed and tilting trains

- Intercity and regional trains,

- Locomotives

- Urban and underground railways

- Local public transport

- Freight transportation

- Special vehicles

Please don’t hesitate to contact us at any time.

Deutsch

Deutsch