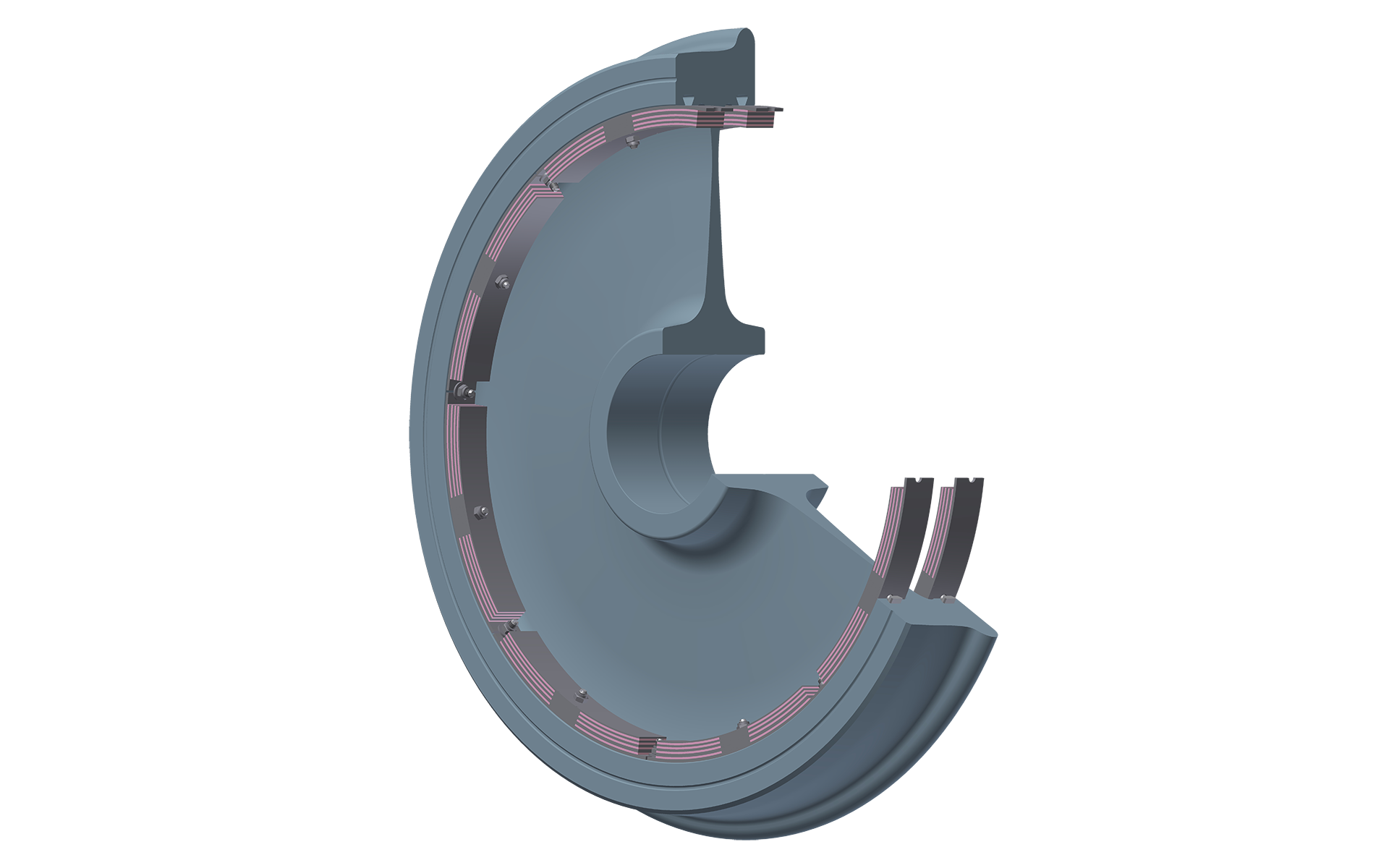

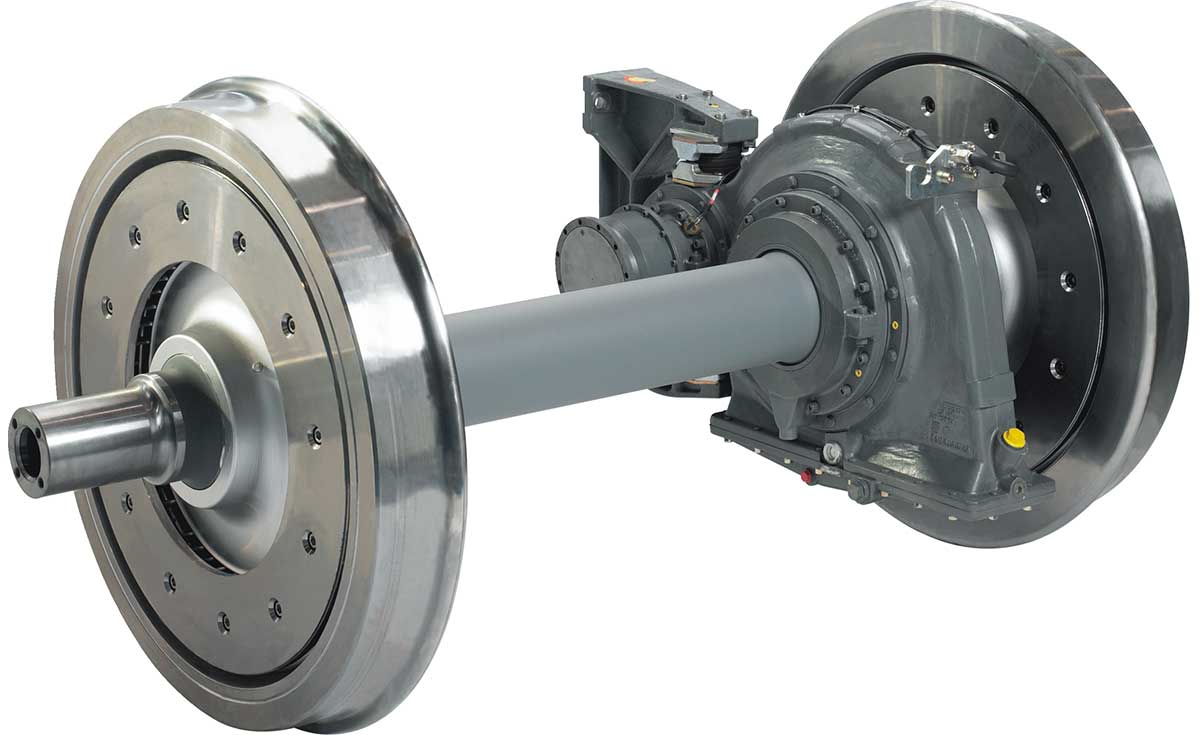

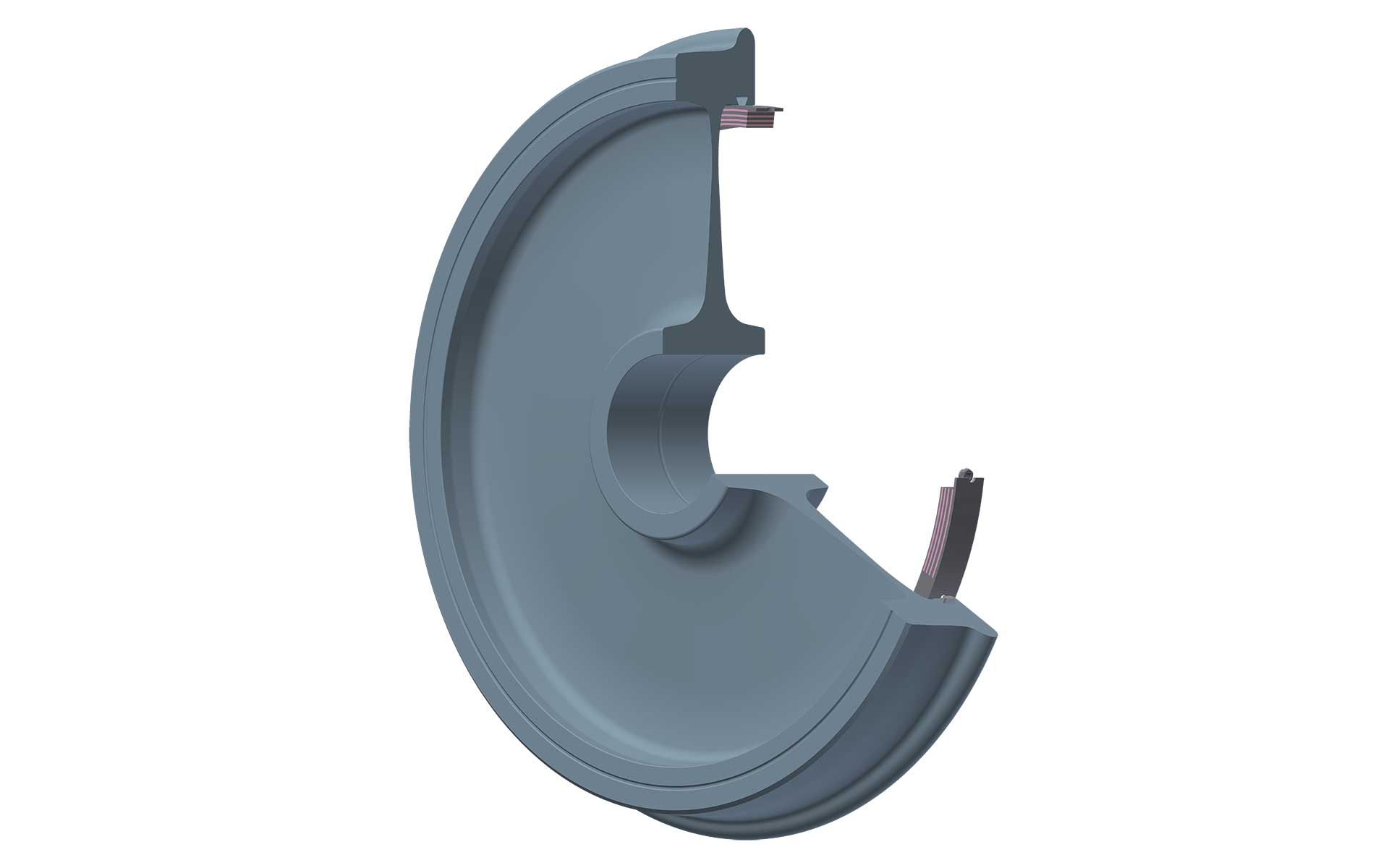

UltraDur ER8H: 265HBW hardness around the wheel tread

The world’s leading high-speed wheel for smooth running and mileage, based on the new UltraDur ER8H material, was developed jointly with one of our OEMs. The requirement profile for use in China was demanding: Speeds up to 380 km/h, temperature fluctuations from -40 ° C to + 45 ° C, humidity up to 95%, resistance to strong winds, rain, snow and acid rain, sandstorms, salt spray etc.

The new UltraDur ER8H high-speed wheels meet all these requirements by increasing the hardness to at least 265HBW evenly around the wheel circumference and in-depth up to the wear line. Of course, it also complies with the demanding material characteristics such as strength and notch impact energy in the wheel flange and fillet as well as the customer’s metallographic specifications regarding microstructure, degree of purity and grain size.

The partially contradictory requirements, e.g. hardness and notch impact, cannot be met without outstanding expertise in the areas of material development and heat treatment. These represent the core competencies of BVV. This is one of the reasons why we are the only ones in the world that have proven the ability to meet Chinese requirements.

Good news for customers around the world who are looking for smooth running and good mileage during high-speed transportation!

Deutsch

Deutsch