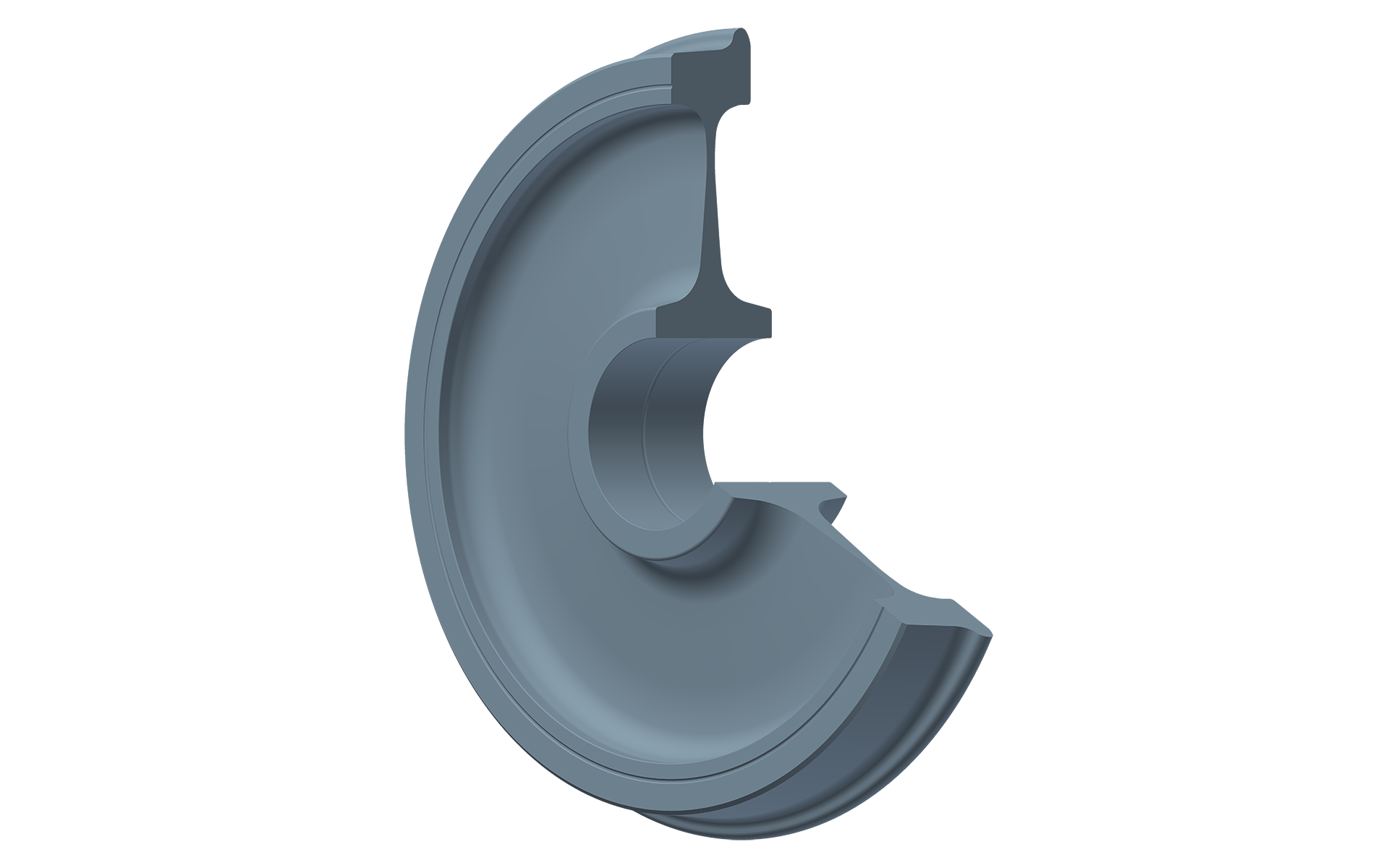

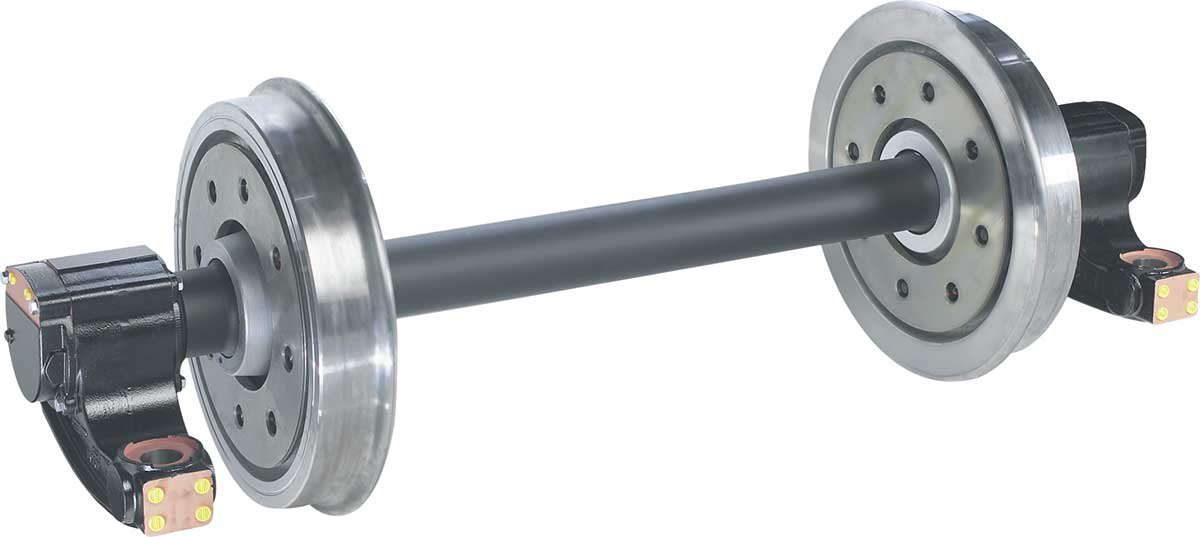

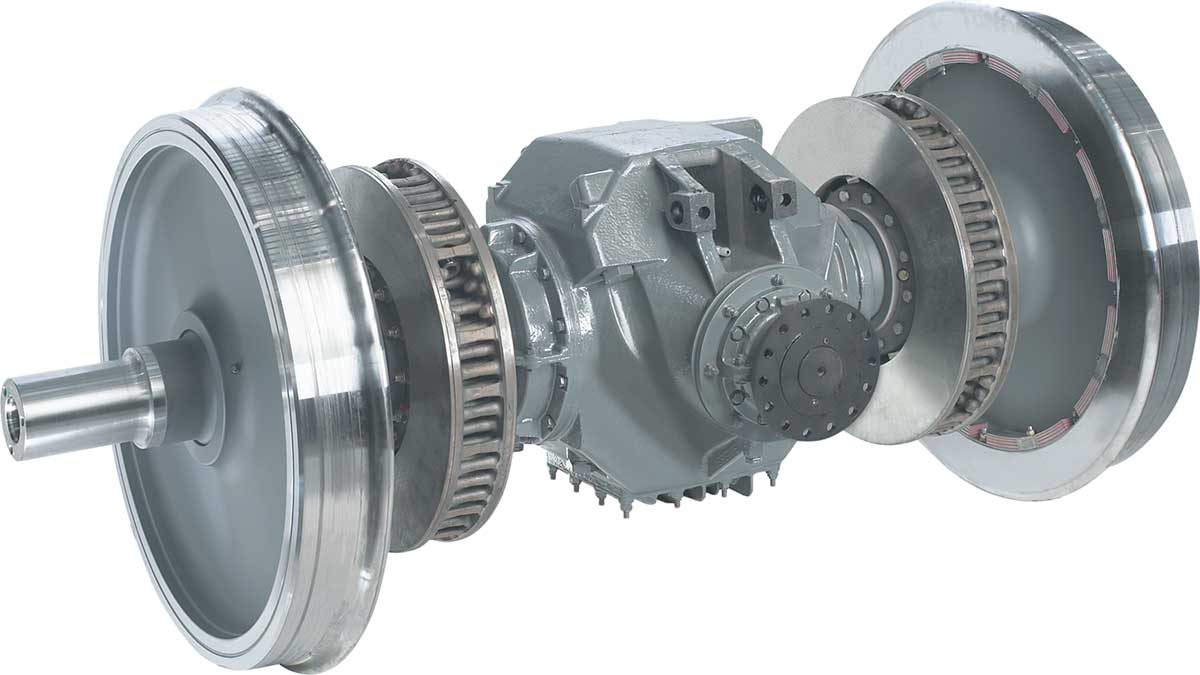

The endurance runner for all speeds below the high-speed transportation range

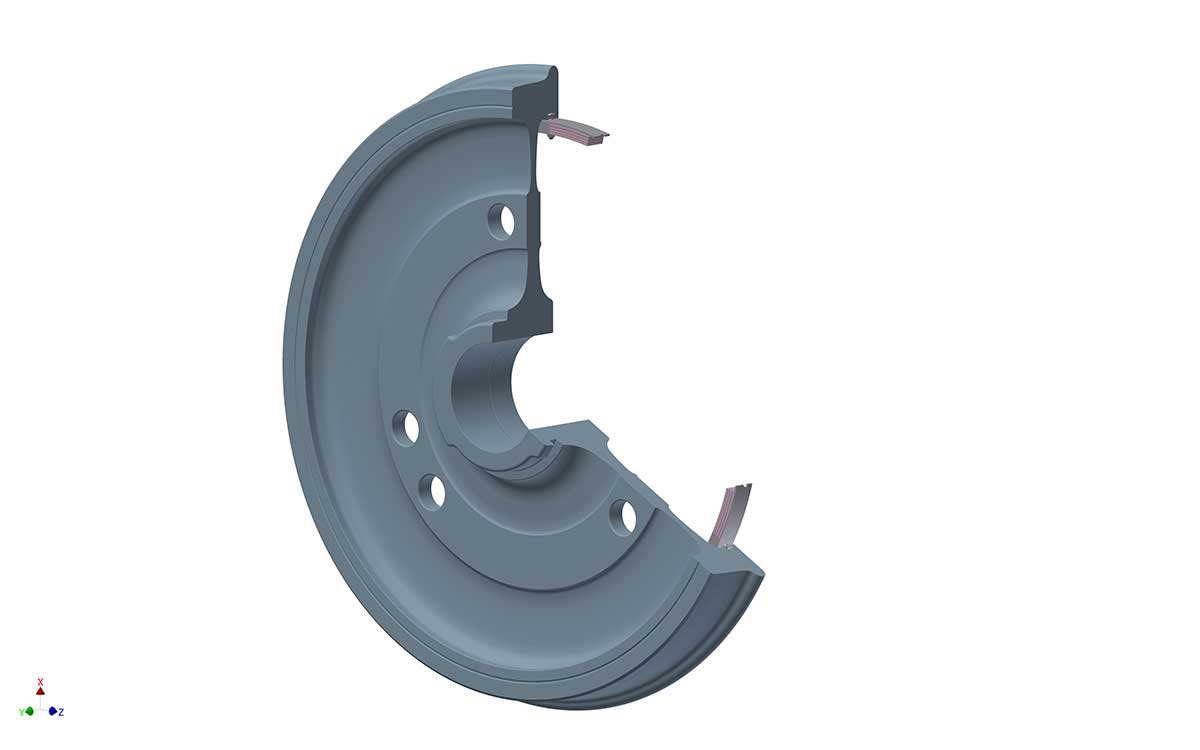

With the BVV monobloc wheel for passenger transport, we present a balanced wheel concept for the speeds demanded of high mileage performance. Like all members of the BVV wheel family, it benefits from the tried and tested materials and manufacturing processes of the high-speed transportation sector, especially the “Advanced Heat Treatment AHT” for outstanding, long-lasting properties. A quality wheel produced from quality German blacksmithing and engineering!

Deutsch

Deutsch