New material developments

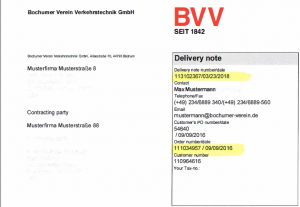

New material developments are comprehensive research projects – always carried out in close cooperation with our customers. This is especially practical where standard limits are tightened and new solutions need to be created. An example:

Customer requirements: Over 40 tonnes per wheelset in continuous operation

OEMs and operators increasingly expect high-strength, high-performance and fatigue-resistant heavy-duty wheelsets for loads over 40 t per wheelset, which can also be used economically for loads under 30 t. Since the common materials, such as Class C according to AAR, already show significant damage to the wheel treads at loads of over 30 t, we have developed a special steel in cooperation with our customers.

The BVV-Solution: Our niobium-based micro-alloyed steel HHR5

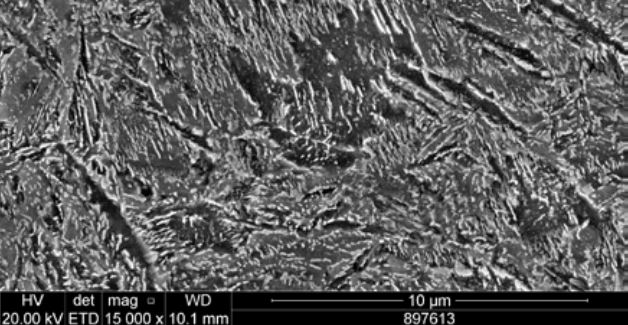

After a comprehensive test series, we decided on a micro-alloy with niobium. Niobium, a rare heavy metal, with its exceptional affinity for carbon, is ideal for forming a high-strength alloy with a fine-grained bainitic-perlitic microstructure.

HHR5 meets all AAR Class D criteria for hardness, fracture toughness, strength properties and fatigue resistance. From this we then forge the high-performance and wear-resistant wheels, which make the carriages more resilient and freight transportation more economical.

Deutsch

Deutsch