Our innovations are inspired by the needs of railway industry

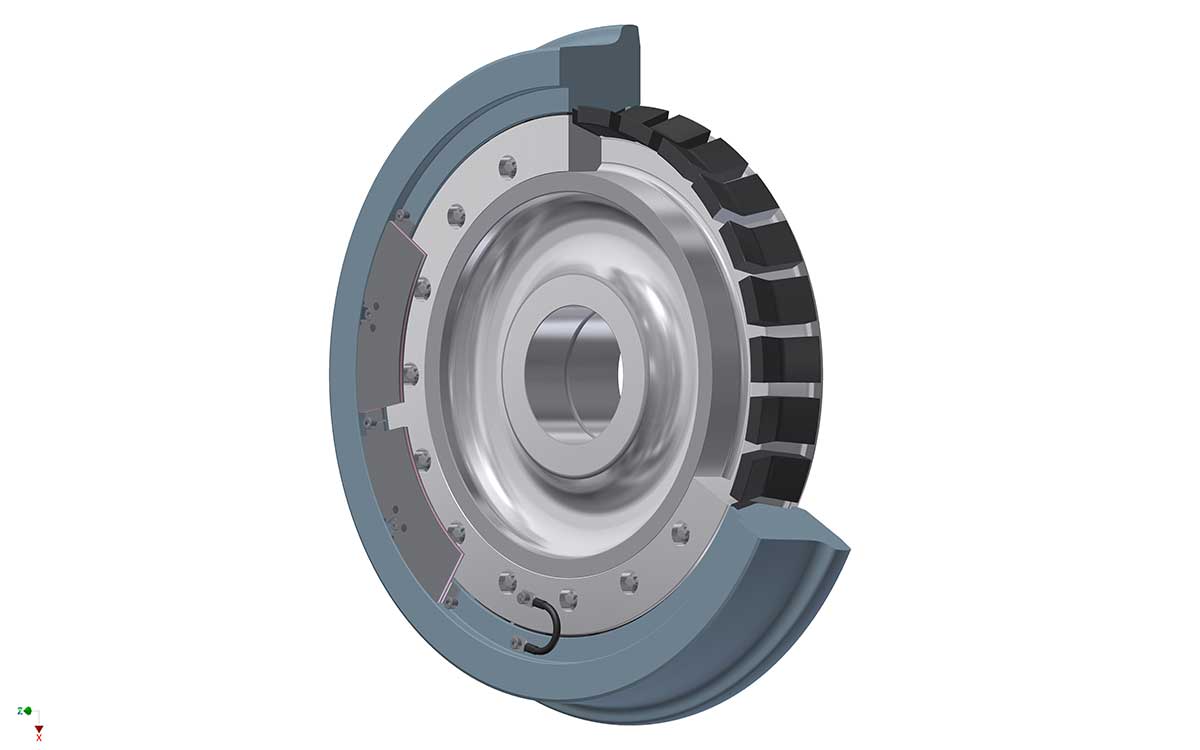

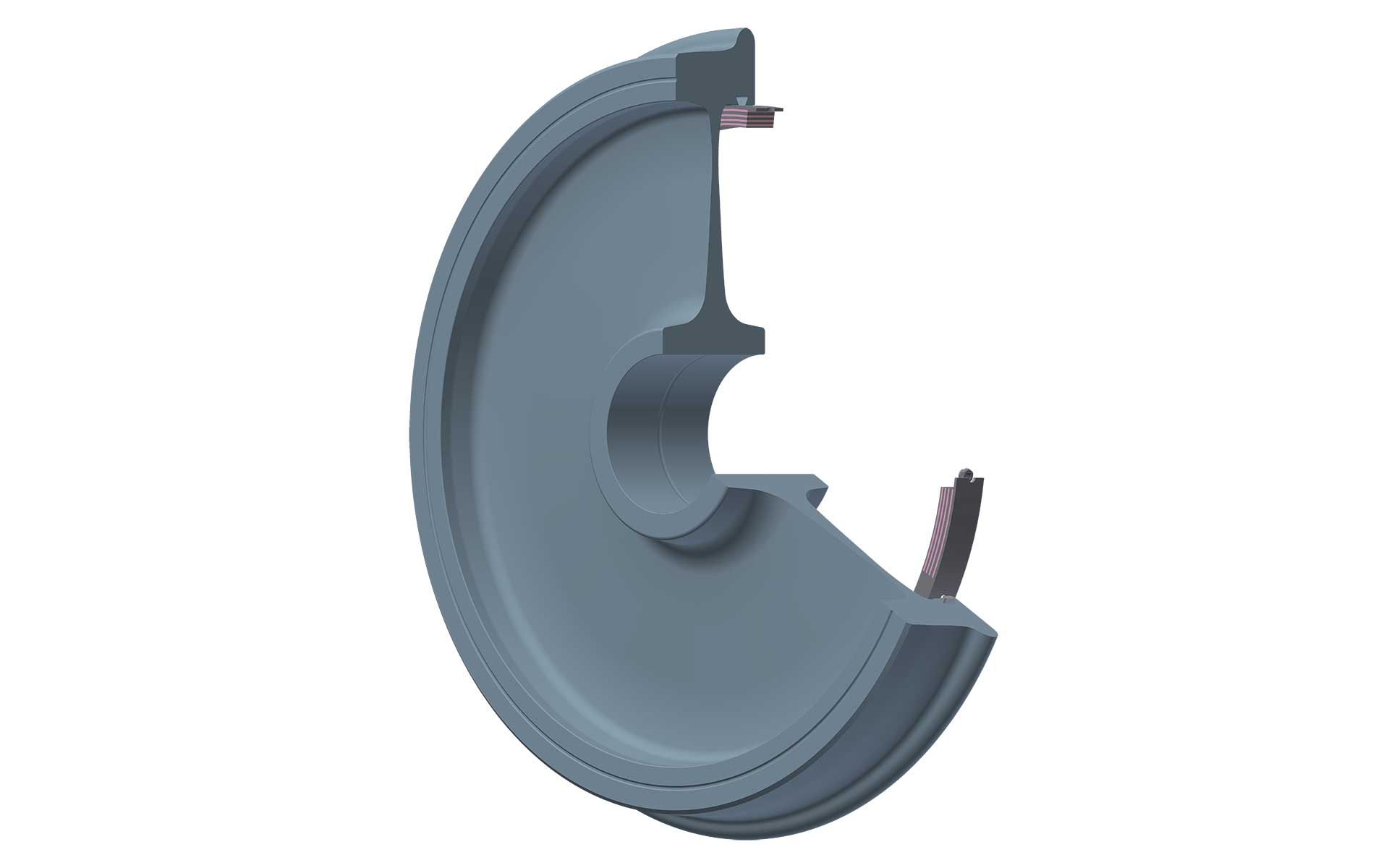

Innovations from the Bochumer Verein – the resilient wheels for local traffic, the stress-balanced solid wheel for passenger and high-speed traffic, deep-cambered solid wheels for block-braked freight and passenger traffic, Highly effective wheel noise absorbers … – they all write a little history, because they are answers to the requirements of time. And because they are profitable for manufacturers and users – Acceptance for their vehicles, market shares, cost savings. We are consistently following this route. In addition to safety, the focus is on three key aspects: the lightweight construction, the acoustics and the service life, because this is where the greatest benefit for our customers lies.

Deutsch

Deutsch